The rest position is the normal resting position of the welding gun. The first step is to load the stud or the refractory anchor into the gun and then load the suitable ferrule with it. They are kept onto the metal surface and held straight. Now the trigger is pressed, and the stud moves forward from the rest position until the welder detects that the stud has touched the metal plate. This is done by the machine, which measures the resistance between the stud and the plate. If the resistance is to high the gun will refuse to fire. This is to ensure that the surface of the plate is free from any oxide scale or dirt.

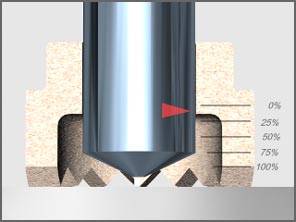

The second position is called Nul Position. This is the point where the stud comes in contact with the steel casing or metal surface. As a contact is made, a current is turned on and the stud moves up at a speed. The current creates an arc but it prevents it from bonding to the metal surface. The stud will move down 4-5mm, this also compensates any errors in length.

Once the stud has reached the appropriate position the main current is passed and now the stud moves up to the final position.

When the stud is at the final height, the main current is automatically monitored. The stud will stay at the final height for a second.

With the current still running, the stud is moved down into the molten weld pool. When the initial nul position is reached the stud is further pushed into the weld pool. As the stud is pushed down, the current is kept on to keep the pool from getting in a solid state.

Reaching a certain height, the current is switched off and the stud then proceeds to solidify. The ferrule gives it a shape which ensures that the refractory anchor is welded fully.

After the weld is cooled the welder removes the gun from the stud and the gun is back to rest position.

After the welding the ceramic ferrule is removed by slightly hammering it. This cycle can be repeated over and over again with the same accuracy. This give an identical welding property to every single stud weld.