Santura engineering provides with various specifications of stud welding machines.

When furnaces undergo repair, all the refractory material is broken down and all the refractory anchors are removed by gauging or grinding. Once this is over and the inner surface of the furnace casing is free from refractory concrete and anchors, the surface is marked to indicate the locations of new refractory anchors to be placed. Before the anchors are installed these positions need to be ground to lean the surface using a grinder.

The used of traditional welding rods will not be required here. Our refractory anchors are designed in a special manner so that it supplies it own weld filler. This weld filler is call flux, which is made of aluminium. With the traditional welding systems the welder will take about 15-20 anchors in a span of 1 hour. Santura engineering can offer to weld these anchors at a rate of 155- 200 anchors per hour, using stud or flash welding machines. This means you need fewer people in the furnace to be able to carry out the same work or same number of people but in a shorter time. This welding process does not emit any toxic fumes, like the traditional methods.

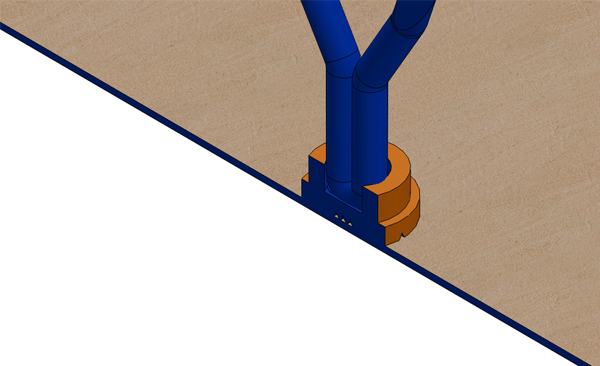

The welder moves the stud in a controlled manner during the weld. The weld is monitored and kept to the pre-set values by the microcomputer. The stud has two reference positions, first position is fixed half way between the extreme travel positions of the pistol, and this position is called rest position.

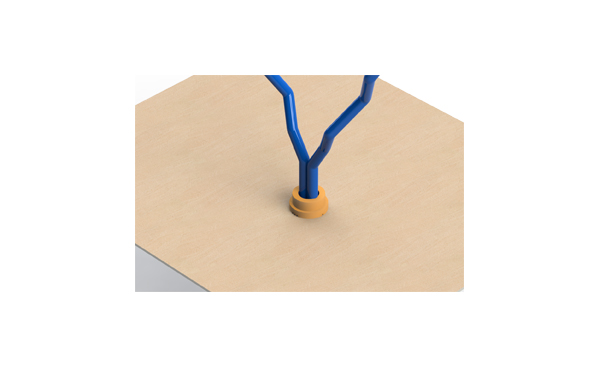

stud welding gun

Application

Application